Egyptian Cement

Your Partner for Durable Construction

Egypt has a long history of high-quality construction, and Egyptian cement is at the forefront of this legacy.

It’s a reliable choice for any construction project, from residential buildings to large-scale infrastructure.

Why Choose Egyptian Cement?

Quality and Durability:

Egyptian cement is produced according to the highest international standards, including European and American specifications. It is known for its exceptional compressive strength and durability, making it ideal for a wide range of applications, including concrete structures, foundations, and roads.

Variety of Products:

Our product range includes different types of cement to meet all project needs, such as Ordinary Portland Cement (OPC), Sulfate-Resisting Cement (SRC), and White Cement. This variety allows you to find the perfect type of cement for your specific project requirements, whether it’s a coastal project that needs to resist corrosion or a decorative project that requires a high-quality white finish.

Competitive Pricing:

Due to Egypt’s strategic location and advanced manufacturing capabilities, we can offer high-quality cement at very competitive prices. This helps you reduce project costs without sacrificing quality.

Geographical Advantage:

Egypt’s strategic location provides easy access to international markets, which ensures fast and efficient shipping to various countries.

Our Products

- Ordinary Portland Cement (OPC):

The most common type of cement, used for general construction and most concrete applications. It provides excellent strength and is easy to use.

- Sulfate-Resisting Cement (SRC):

Ideal for projects in aggressive environments, such as coastal areas, foundations, and drainage systems, as it protects against sulfate attacks.

- White Cement:

Used for decorative purposes, high-end finishing, and producing white concrete. It’s a key choice for architectural projects that require a clean and bright finish.

Technical Specifications and Certifications

Egyptian cement isn’t just known for its general quality; it is also backed by rigorous technical standards and international certifications. This reassures importers of its reliability and performance in various climates and applications.

- International Standards:

Egyptian cement factories adhere to both Egyptian Standards (ES) and a wide range of international standards, including EN (European Norms) and ASTM (American Society for Testing and Materials). This ensures that the cement is compatible with construction projects worldwide.

- Quality Control:

Each batch of cement undergoes strict quality control tests in certified laboratories to ensure its compliance with strength, setting time, and chemical composition specifications.

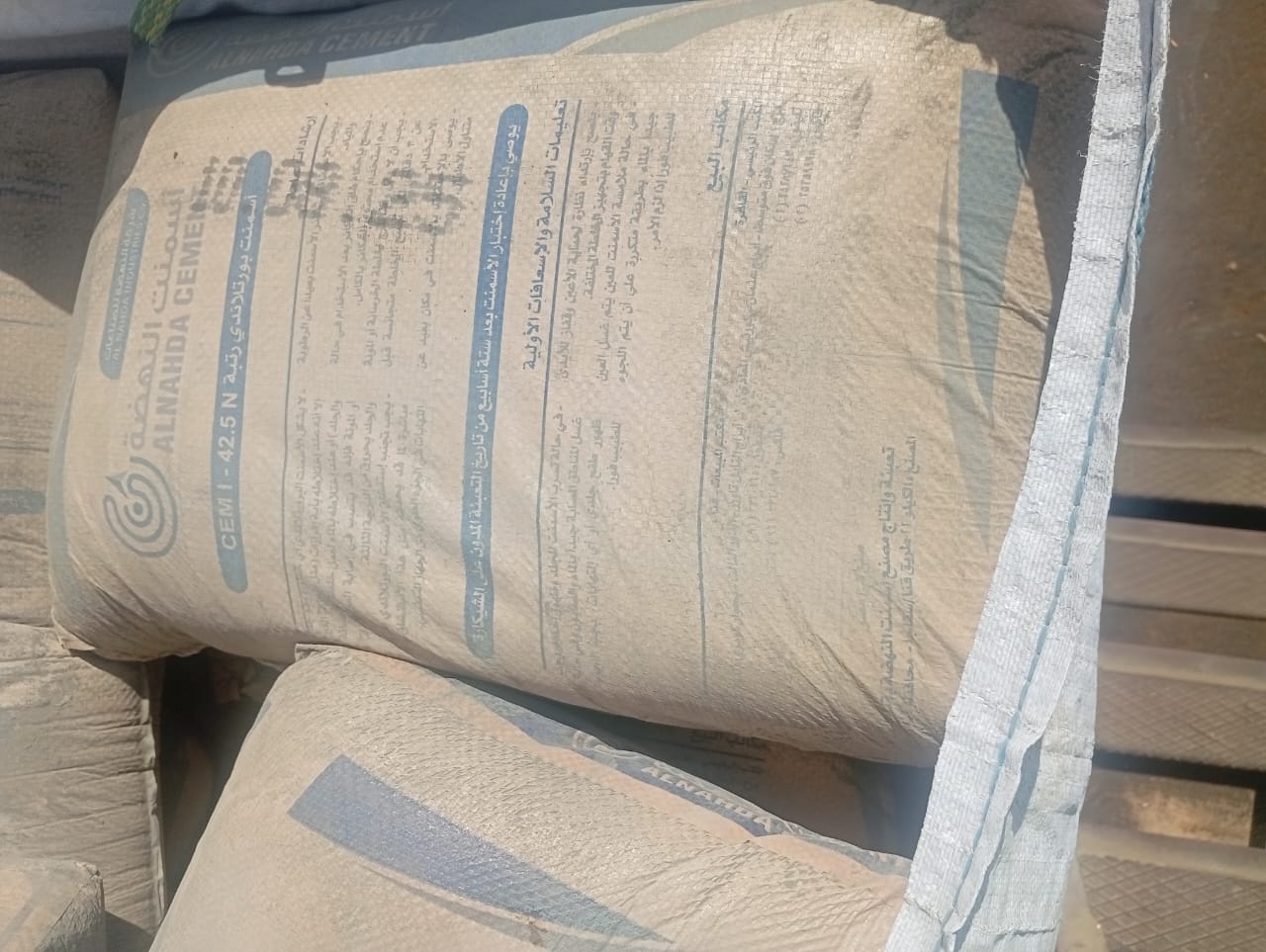

Egyptian Portland Cement (CEM I) – Technical Specifications

This table shows the typical properties of Ordinary Portland Cement (OPC), the most common type for export

| Property | Standard | Requirement / Range | Explanation for Importers |

|---|---|---|---|

| Cement Type | ES 4756-1 / EN 197-1 | CEM I | This is the designation for pure Portland cement with a minimal amount of other constituents (up to 5%). It signifies a high-quality, standard product. |

| Compressive Strength | (at 28 days) |

Grade 42.5 N: ≥ 42.5 MPa Grade 52.5 N: ≥ 52.5 MPa |

This is the most critical measure of cement quality. It indicates the final strength the concrete will achieve. Egyptian factories produce grades 42.5 and 52.5, which are suitable for a wide range of projects, from residential buildings to high-rise structures. |

| Early Strength | (at 2 days) |

Grade 42.5 N: ≥ 10.0 MPa Grade 52.5 N: ≥ 20.0 MPa |

Important for projects that require rapid formwork removal or accelerated construction schedules. “N” stands for “Normal” early strength. “R” for “Rapid” strength is also available. |

| Initial Setting Time | ES 4756-1 | ≥ 60 minutes | This property indicates the time available for mixing and placing concrete before it begins to harden. A longer time is often preferred for large projects and hot climates. |

| Fineness (Blaine Method) | Typically > 3000 cm²/g | The fineness of the cement powder, which affects its hydration rate and strength development. Finer cement generally gives higher early strength. | |

| Sulfate Content (SO₃) | ES 4756-1 | ≤ 3.5% | A low sulfate content is crucial for the long-term durability of concrete, as high sulfates can cause expansion and cracking. This is a key chemical specification. |

| Chloride Content (Cl⁻) | ES 4756-1 | ≤ 0.10% | A very low chloride content is essential to prevent the corrosion of steel reinforcement within concrete structures. This is a critical factor for reinforced concrete projects. |

| Loss on Ignition (LOI) | ES 4756-1 | ≤ 5.0% | Measures the amount of water and carbon dioxide driven off by heating. A low value indicates proper production and storage, ensuring product freshness. |

| Insoluble Residue | ES 4756-1 | ≤ 5.0% | The amount of material that does not dissolve in acid. A low value indicates a high degree of purity and quality of the cement. |

| Soundness (Le Chatelier Expansion) | ES 4756-1 | ≤ 10 mm | This test measures the dimensional stability of the cement after it hardens. A low expansion value ensures the final concrete will not crack due to expansion. |

Important Notes for Importers:

- International Harmonization:

All our products comply with both the Egyptian Standard (ES 4756-1) and the corresponding European Standard (EN 197-1). This ensures that the cement meets the strictest international quality and performance criteria.

- Custom Orders:

We can also provide other cement grades and types, such as Sulfate-Resisting Cement (SRC) and White Cement, with specifications tailored to your specific project needs.

- Quality Certificates:

Every shipment is accompanied by a certificate of analysis, confirming that the product meets the specified standards.

- CEM II Cement Specifications Table:

CEM II, also known as Portland Composite Cement, is a family of cements that incorporates other materials like slag, fly ash, or limestone to improve certain properties and reduce its environmental impact. It’s a common type of cement exported from Egypt, and its specifications align with the Egyptian Standard ES 4756-1 (which is equivalent to EN 197-1).

Here is a table showing typical specifications for a common CEM II type, CEM II/A-L 42.5 N (Portland Limestone Cement), with explanations for importers.

Egyptian Portland Composite Cement (CEM II) – Technical Specifications

| Property | Standard | Requirement / Range | Explanation for Importers |

|---|---|---|---|

| Cement Type | ES 4756-1 / EN 197-1 | CEM II/A-L (Other types like CEM II/B-L also available) |

A-L signifies a blend of Portland cement clinker and limestone (L). The “A” and “B” designate the percentage of limestone (A: 6-20%, B: 21-35%). This type offers reduced heat of hydration and improved workability. |

| Compressive Strength | (at 28 days) | Grade 42.5 N: ≥ 42.5 MPa | This is the minimum final strength. The “N” indicates normal early strength. Many Egyptian CEM II cements are produced to meet this high standard, making them suitable for structural concrete applications. |

| Early Strength | (at 2 days) | Grade 42.5 N: ≥ 10.0 MPa | A strong early-strength value ensures that concrete can be used in projects that need a fast turnaround, such as pre-fabricated elements or for formwork removal. |

| Initial Setting Time | ES 4756-1 | ≥ 60 minutes | The time before the cement starts to harden. The extended setting time of CEM II is beneficial in hot climates, allowing more time for mixing, transport, and pouring. |

| Fineness (Blaine) | ES 4756-1 | Typically 3200-4000 cm²/g | A measure of particle size. The fineness of CEM II is often higher than CEM I, which can contribute to better workability and a denser, more durable final product. |

| Sulfate Content (SO₃) | ES 4756-1 | ≤ 3.5% | This chemical limit ensures the long-term durability of the concrete, preventing damage from sulfate attacks, which is especially important in environments with high sulfate concentrations in soil or water. |

| Chloride Content (Cl⁻) | ES 4756-1 | ≤ 0.10% | A low chloride content is critical for preventing corrosion of steel reinforcement inside concrete, which is a key factor for the longevity of reinforced concrete structures. |

| Loss on Ignition (LOI) | ES 4756-1 | ≤ 5.0% | Measures the amount of water and carbon dioxide that are lost when the cement is heated. A low LOI indicates the product is fresh and has been stored properly. |

| Soundness (Expansion) | ES 4756-1 | ≤ 10 mm | This test ensures the cement will not undergo excessive volume changes after hardening, which could lead to cracking and structural instability. |

Benefits of CEM II for Importers

- Sustainability:

CEM II’s composition includes materials like limestone, reducing the need for energy-intensive clinker production. This makes it an eco-friendly option with a lower carbon footprint, appealing to clients with green building initiatives.

- Enhanced Durability:

The mineral additives in CEM II improve the long-term properties of concrete, making it more resistant to chemical attacks and reducing its permeability.

- Cost-Effectiveness:

The inclusion of supplementary materials in CEM II production can result in a more competitive price compared to pure Portland cement (CEM I), providing a cost advantage without sacrificing quality.

- Versatile Applications:

CEM II is highly versatile and used in a wide range of applications, including concrete for roads, foundations, and reinforced structures, as well as for masonry, plastering, and pre-cast concrete elements.